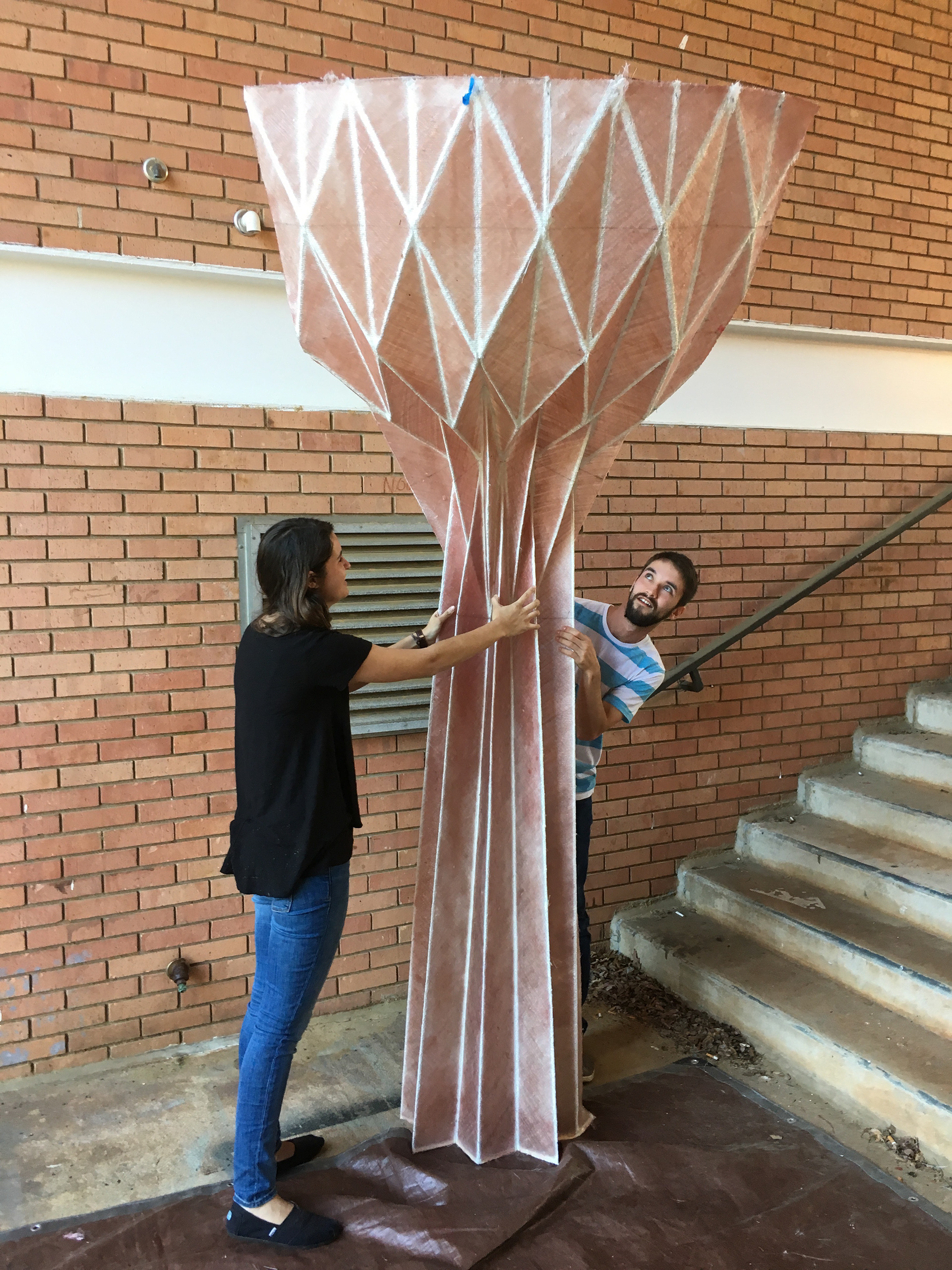

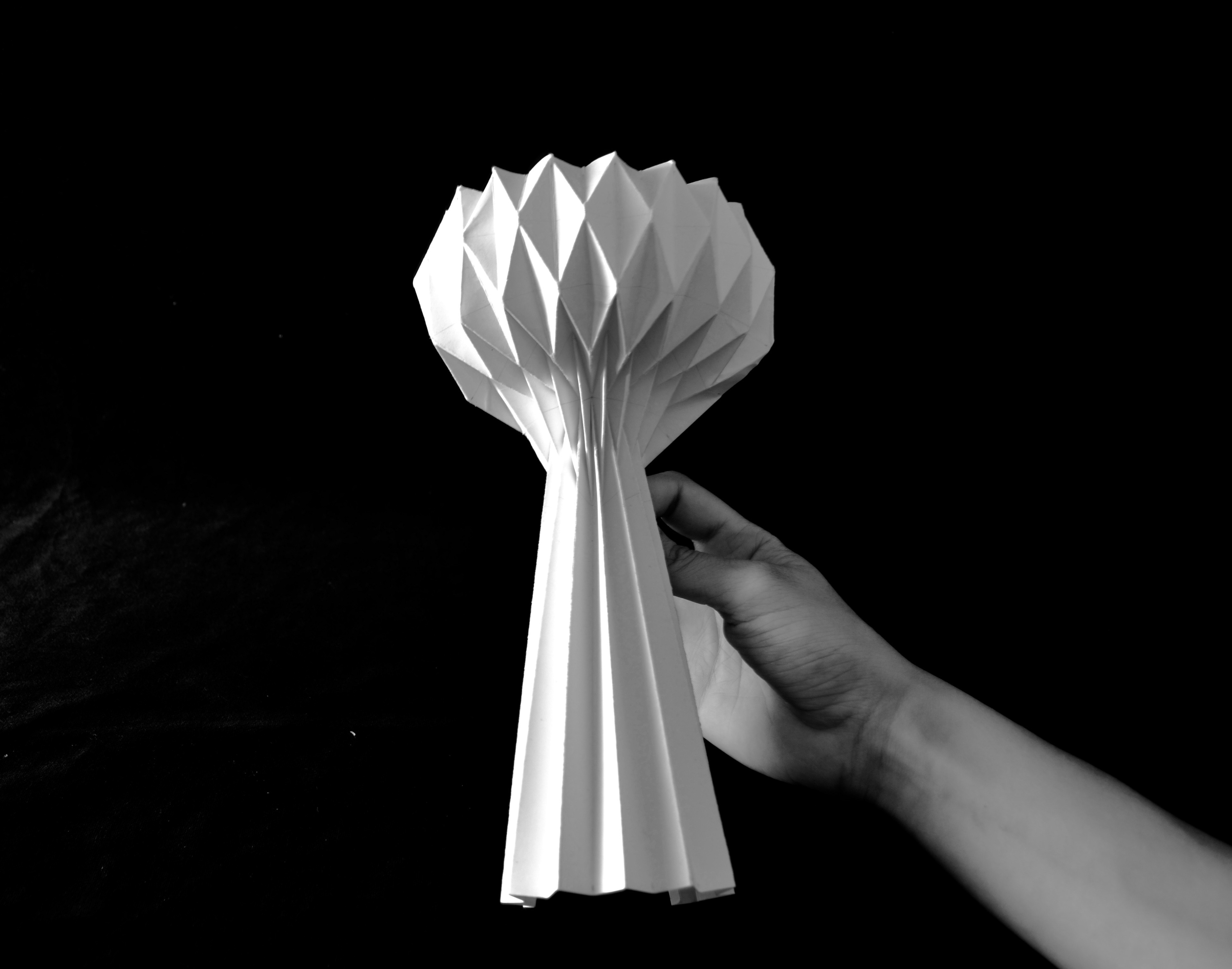

The objective of this project is to eliminate traditional moldmaking methods by applying folding techniques that exploit Fiberglass Reinforced Plastic’s natural qualities as a flexible textile, in order to create a complex and structural full scale column.

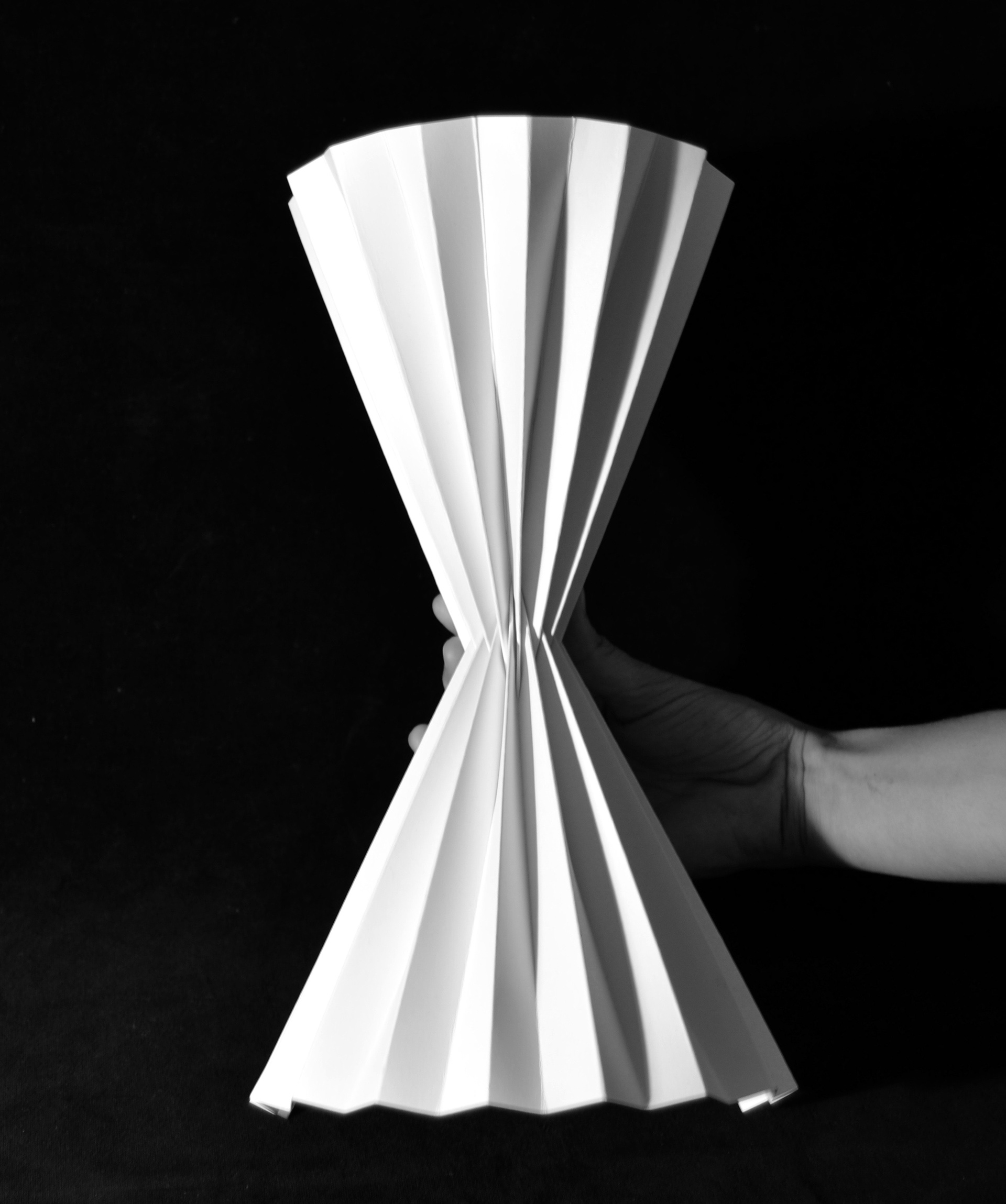

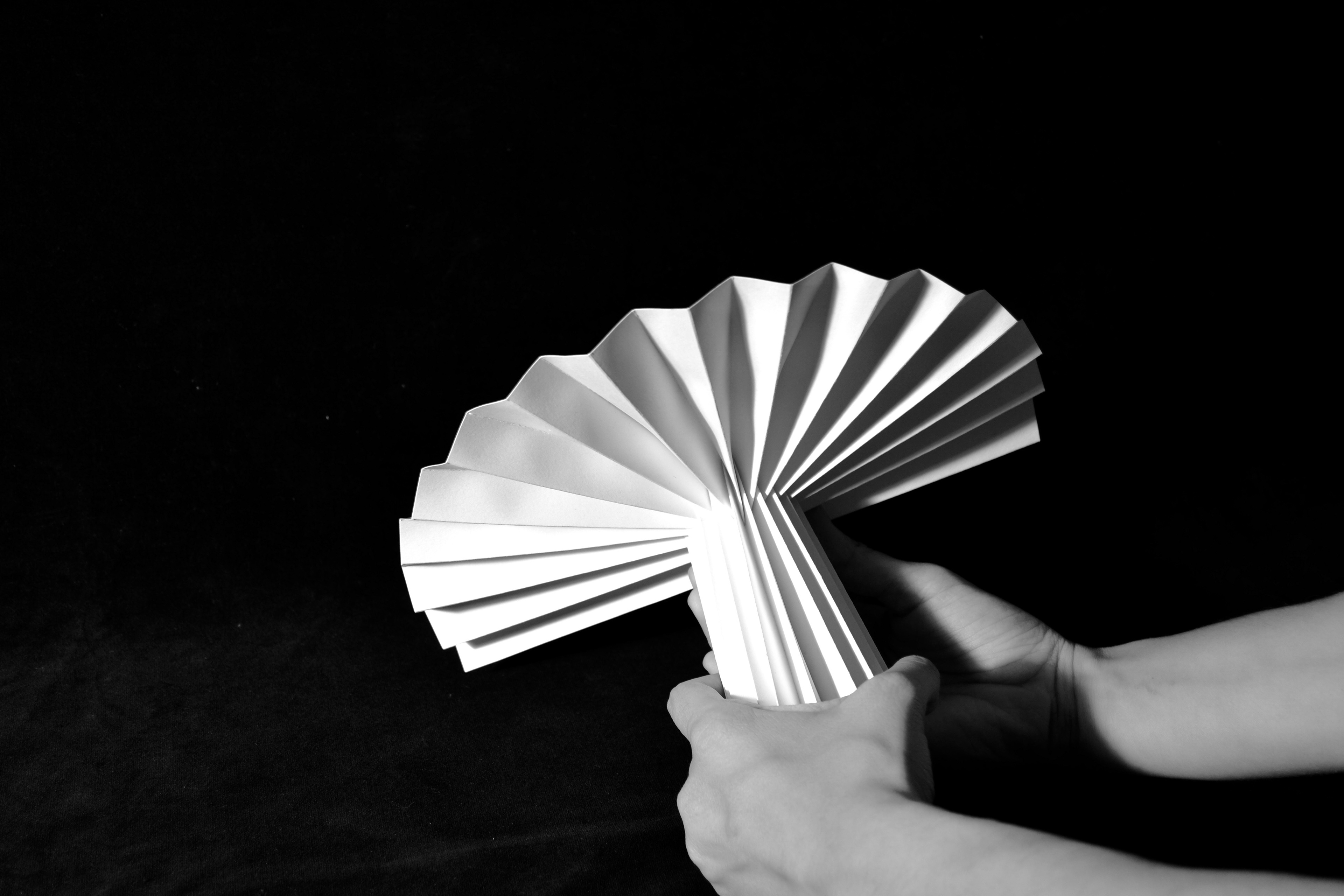

By employing folding and eradicating mold-making, we are able to create complex structures that reduce the duration and cost of the fabrication process while also adding additional strength to the material and allowing for flat packing and shipping the panels.

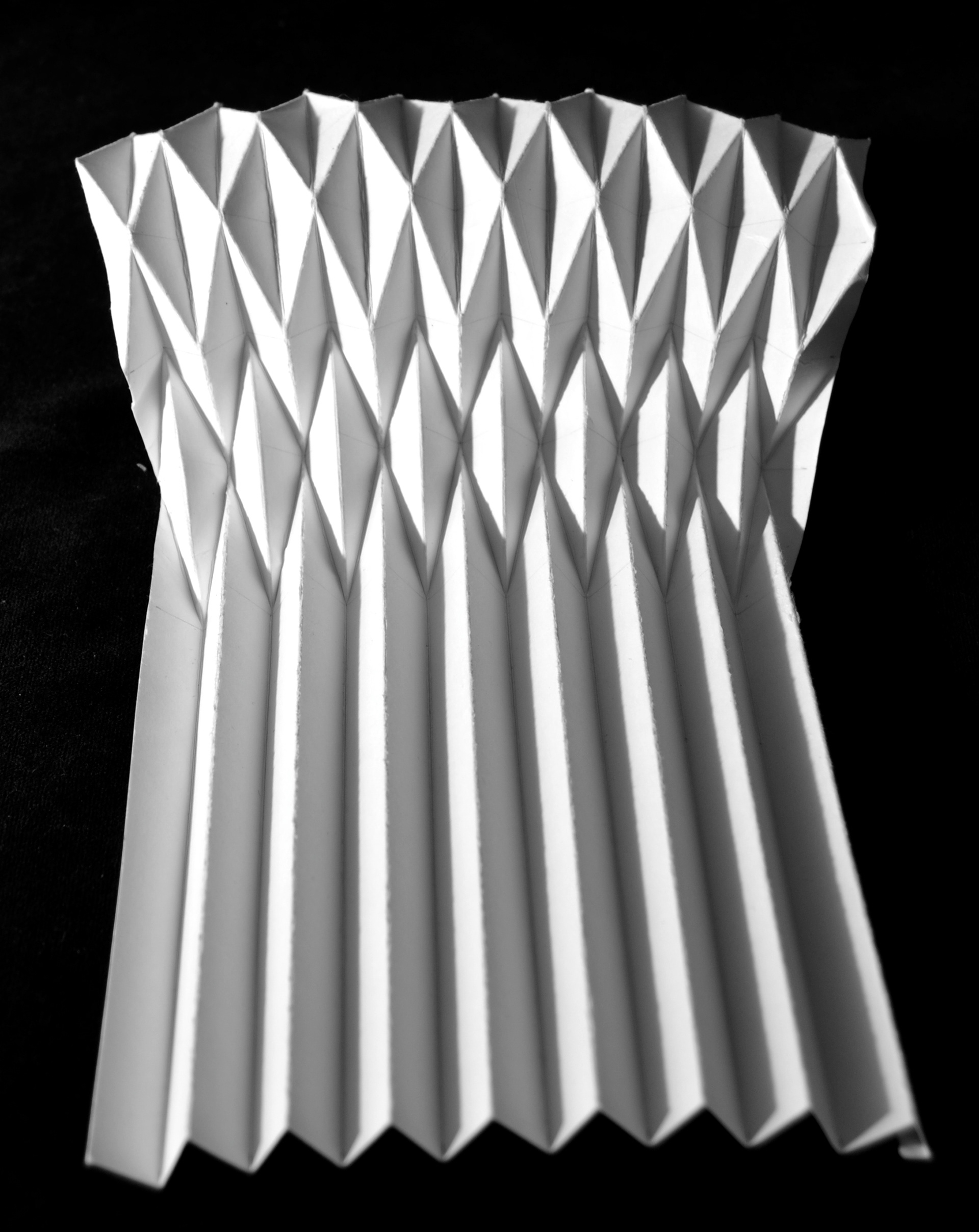

step1. tape folding pattern

step2. brush on resin

step3. allow resin to cure

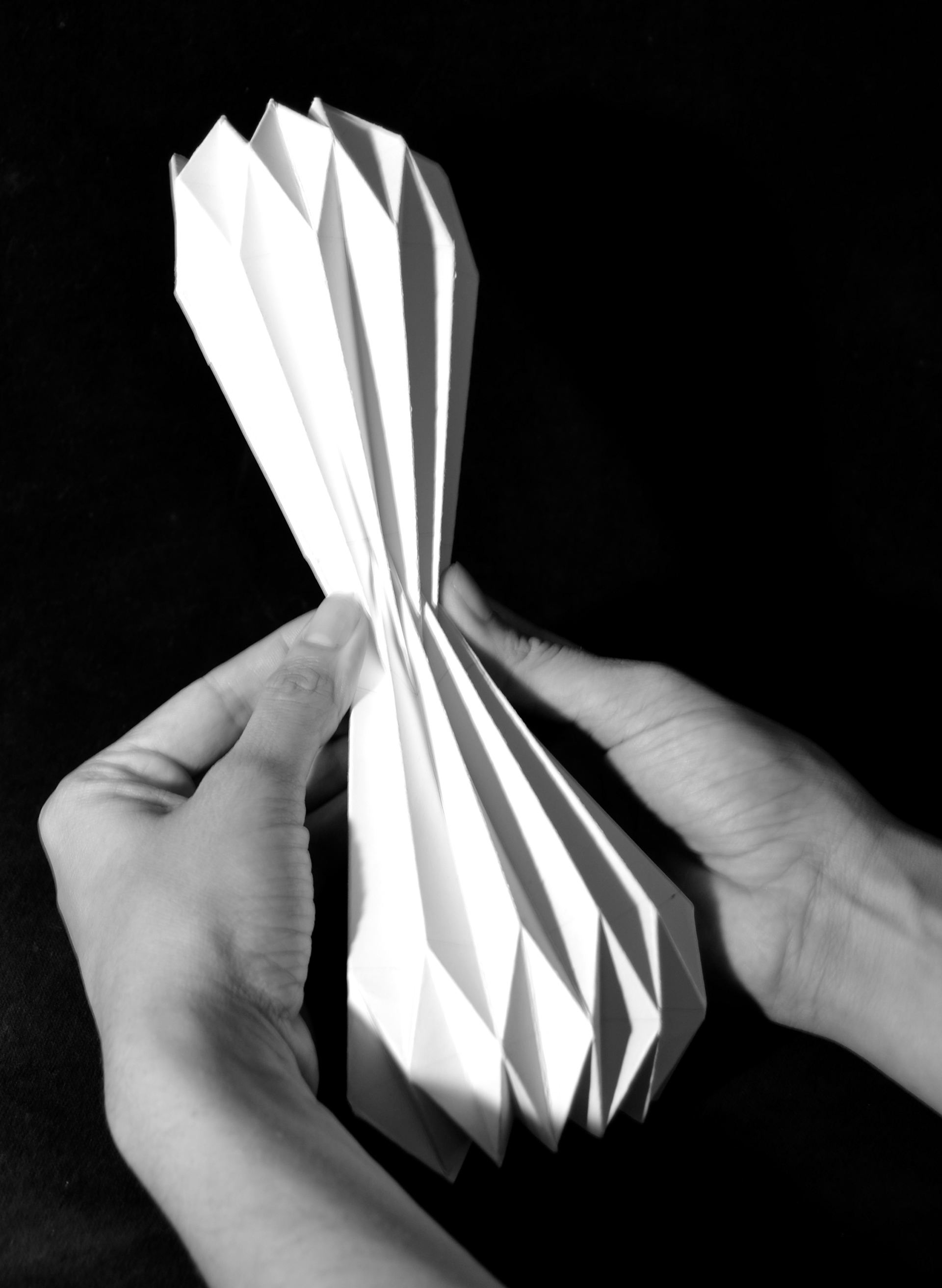

step4. fold frp along crease pattern

step5. secure column in final position

Adding folds to a sheet material augments its rigidity and increases its load carrying capacity. We translated this technique to fiberglass by inventing a new sequential manufacturing process, in which resin is applied only to certain portions of the fiberglass cloth. The areas without resin function as hinges that allow the surface to fold along them. After it is folded into place, resin is applied to the seams to complete the structure. Before resin is applied to the seams, the parts can be easily flat packed and shipped to the destination.

The culmination of this project is a full scale prototype of the fibre reinforced column design The project won First Prize in the ACMA Composites Design Challenge and was presented at the 2017 AIA convention The design also led to a patent for the fabrication process.